Transair® Stainless Steel Pipe Installation Instructions 3/4"(22mm) & 1"(28mm)

< Back to Previous Page

Sound engineering practice for the optimization of an air pipe system

■ When installing a Transair® system, work should be performed in accordance with good engineering practice.

■ Bends and bypasses represent sources of pressure drop.

■ Keep in-line pipe diameter reductions to a minimum.

■ The diameter of the pipe will influence pressure drop and the operation of point-of-use equipment.

■ Select the diameter according to the required flow rate and acceptable pressure drop at the point of use.

■ Never encase the network in a hard solid mass, in order to facilitate maintenance or servicing.

■ To insulate Transair® industrial water systems thermally, we recommend insulating the Transair® stainless steel pipes.

■ Position drops and feeds to take-off points as close as possible to the point of use.

■ When installing a Transair® system, work should be performed in accordance with good engineering practice.

■ Bends and bypasses represent sources of pressure drop.

■ Keep in-line pipe diameter reductions to a minimum.

■ The diameter of the pipe will influence pressure drop and the operation of point-of-use equipment.

■ Select the diameter according to the required flow rate and acceptable pressure drop at the point of use.

■ Never encase the network in a hard solid mass, in order to facilitate maintenance or servicing.

■ To insulate Transair® industrial water systems thermally, we recommend insulating the Transair® stainless steel pipes.

■ Position drops and feeds to take-off points as close as possible to the point of use.

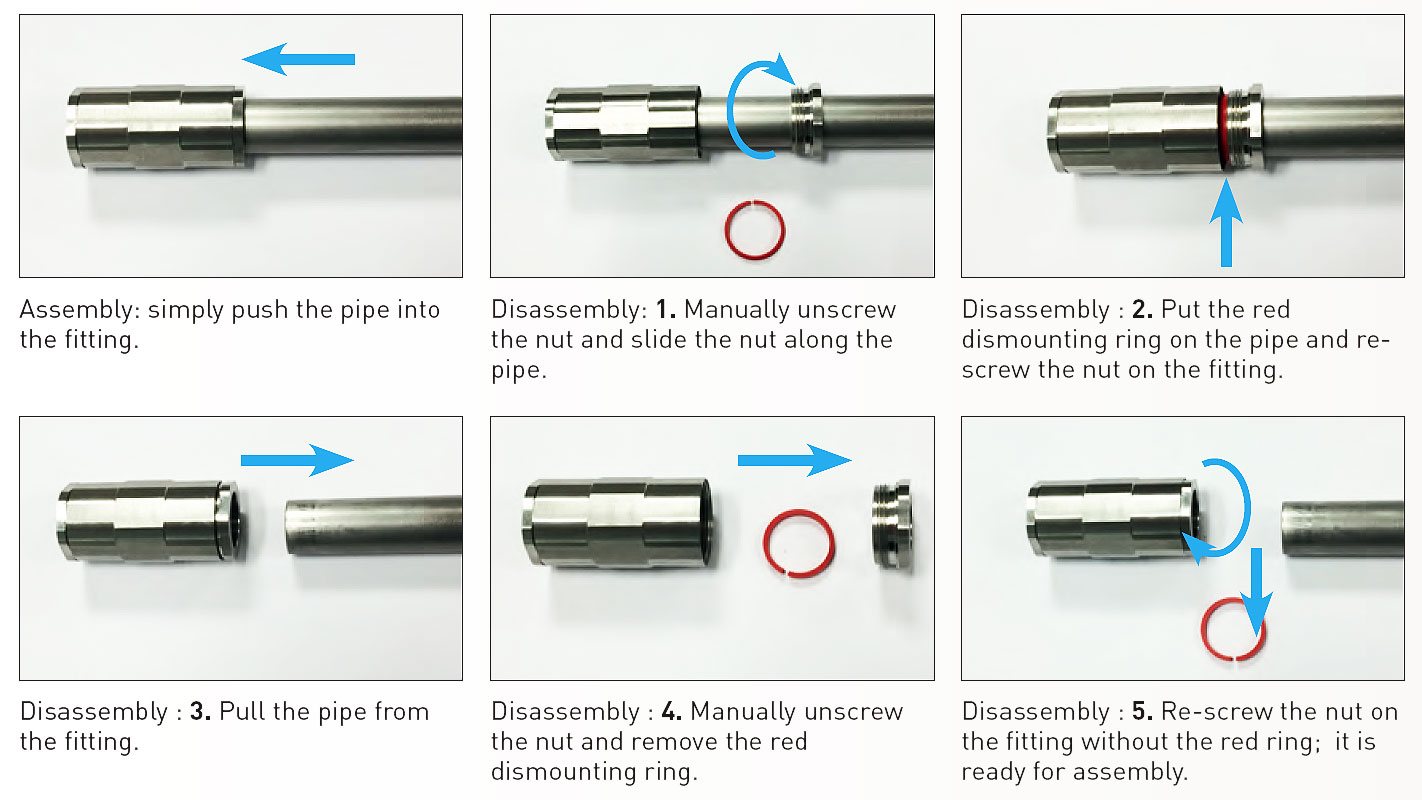

Click For Larger View

3/4"(22mm) 316L Stainless Steel Drop Connector Instructions

Click For Larger View

3/4"(22mm) 316L Stainless Steel Drop Connector InstructionsUnion RF06 N7 02, Elbow RF02 N7 02, NPT Adapter RF05 N7N06,

Tools

Click Here for the Tools Page

Pipe Cutter for Aluminum Pipe

Pipe Cutter for Aluminum Piperef. 6698 03 01

Chamfer Tool for Aluminum Pipe

Chamfer Tool for Aluminum Piperef. 6698 04 01

Deburring Tool for Aluminum Pipe

Deburring Tool for Aluminum Piperef. 6698 04 02

Dismounting Tool

Dismounting Toolref. EW11 00 01

Marker Pen

Marker PenProcedure

1. Cutting the pipe:

■ place the pipe in the pipe cutter

■ position the blade onto the pipe

■ rotate the pipe cutter around the pipe while gently tightening the wheel.

■ place the pipe in the pipe cutter

■ position the blade onto the pipe

■ rotate the pipe cutter around the pipe while gently tightening the wheel.

2. Carefully chamfer the outer edges.

3. Deburr the inner end of the pipe.

4. Mark the connection indicator.

Connection

✉ Email this Page

Also Available from mdi

|

TransairPipeSales.com is owned and operated by mdi, Manufacturers Distributor, Inc. mdi is an Authorized Parker Transair Piping System Distributor. Click Here to view the mdi Line Sheet. |