Transair® Aluminum Pipe

Installation Instructions 2"(50mm) – 2-1/2"(63mm)

< Back to Previous Page

Installation Guidelines

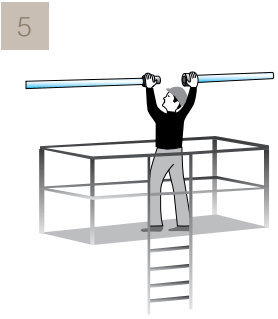

1. Transair pipe and hoses: Transair pipe should be protected from

mechanical impact, particularly if exposed to collision with fork-lift trucks

or when sited in an environment with moving overhead loads. Similarly,

rotation of the pipe and pipe supports should be avoided. Transair pipe

must not be welded.

2. Expansion and contraction: Expansion and contraction of the system

should be calculated prior to installation. The system designer and installer

should calculate the elongation or retraction of each Transair line

according to the recommendations in this installation guide.

3. Situation to avoid: Installation within a solid mass (concrete, foam, etc.),

the hanging of any external equipment to Transair pipe, the use of Transair

for grounding or as a support for electrical equipment, and exposure to

chemicals that are incompatible.

4. When assembling Transair connectors, do not interchange the nuts

with different Transair bodies due to our calibration process.

Tools

Click Here for the Tools Page

Pipe cutter for aluminum pipe

Pipe cutter for aluminum piperef. 6698 03 01

Chamfer tool for aluminum pipe

Chamfer tool for aluminum piperef. 6698 04 01

Deburring tool for aluminum pipe

Deburring tool for aluminum piperef. 6698 04 02

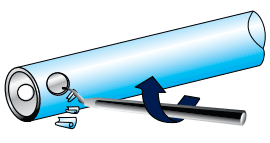

Drilling jig for aluminum pipe

Drilling jig for aluminum piperef. 6698 01 03

Drilling tool for aluminum pipe

Drilling tool for aluminum piperef. 6698 02 01

Drill

Drill

Procedure

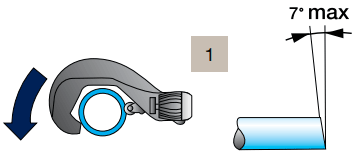

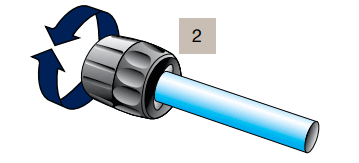

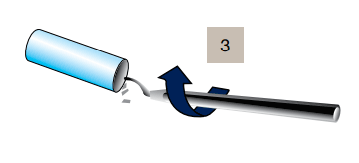

place the pipe in the pipe cutter position the blade onto the pipe rotate the pipe cutter around the pipe while gently tightening the wheel.

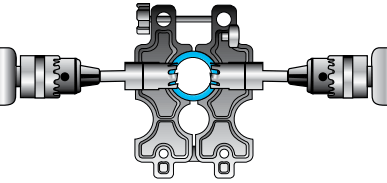

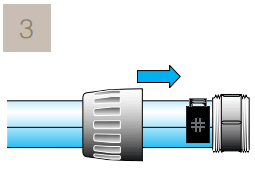

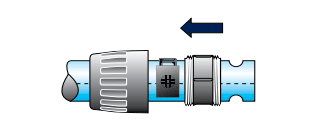

Connection

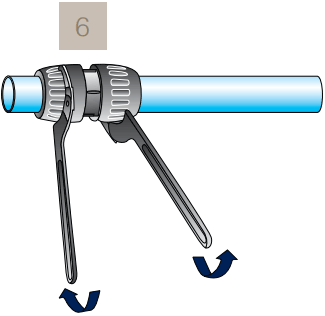

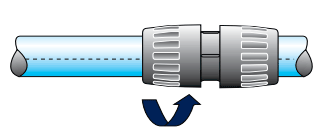

Disconnection

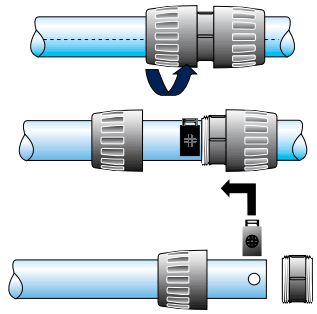

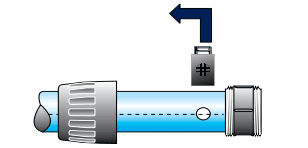

Lateral Dismantling

Back to Main Training Page

Also Available from mdi

|

TransairPipeSales.com is owned and operated by mdi, Manufacturers Distributor, Inc. mdi is an Authorized Parker Transair Piping System Distributor. Click Here to view the mdi Line Sheet. |